Flexible Packaging Solution

Client Request:

• Client required a very flexible solution to run a wide variety of products in short batches catering to the cook at home meal delivery market

• Ability to be changed over quickly with zero waste was key

Objective:

• Deliver a highly flexible packaging solution that was efficient and could handle a wide variety of products with no waste

Discovery:

• The first challenge was handling such a wide variety of products such as leafy greens, diced vegetable, potatoes, green beans, and quinoa to name a few

• Secondly, the client produces small batches with multiple changeovers highlighting the need to design a conveying solution to minimize waste and downtime due to cleaning

Solution:

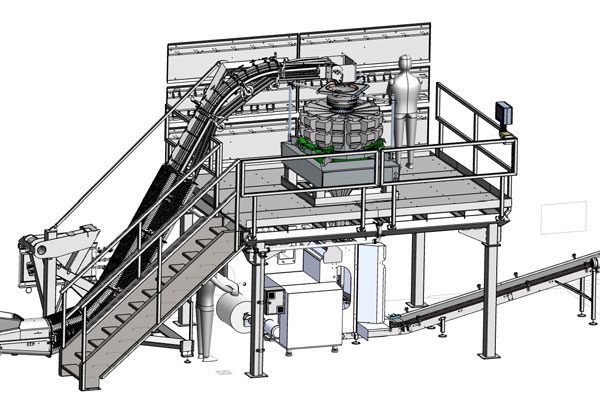

• A Multipond Combination Weigher with a set of change parts was used to accommodate all the various products. Flat feed trays for free-flowing products (Potatoes, Quinoa, Peas) and angled feed trays for non-flowing product (Leafy Greens, Chopped Onions), this is unique feature of Mulitpond

• To address the cleaning and waste concern, a Liftvrac system, flightless incline conveyor allowing a scraper at the discharge to release 100% of the product on to the Multipond

• Additionally the Liftvrac was equipped with a CIP (Clean-in-Place) feature aiding the change-over process.

• For the packaging solution we provided a GEA SmartPacker to produce the pouch with a thermal transfer printer to identify the product and expiry date

• Mezzanine with wash wall and controls to integrate the process