Vezet B.V. is one of the largest vegetable and fruit processing businesses in the Netherlands and leads the market in freshly chopped ready-to-cook vegetables.

Vezet’s cutting-edge vegetable chopping facility produces a range of about 250 different products. The family-owned enterprise aims to be the best and most progressive developer, producer and highly valued supplier of processed vegetables and fruit for immediate consumption. At present about 220 million bags per year are packed; of these approx. 180 million bags are supplied to the Albert Heijn supermarket chain in the Netherlands. The company’s aims are high – the objective is to increase the number of bags company-wide to over 300 million bags in the next 5 years. There are plans to add new capacity and to automate further during this. Therefore, an additional line was recently put into operation to pack ready-to-eat salads. Previous positive project experiences with Multipond weighing systems meant MULTIPOND was relied on exclusively in the process.

The line itself involves a bowl line located in the plant’s high-care section. The bowls are filled with various ready-to-eat salads consisting of a main ingredient, for example different leaf salads or cooked noodles and several salad toppings like shrimp, chicken, mozzarella, olives, pineapple, and mandarins right up to small pieces of beef or boiled egg. Depending on the recipe, the target weights are between 10 g and 150 g. General manager Hans Boshuizen comments: “In packaging products of this type, the market demand for bowls is steadily increasing. So, it became imperative to invest in an additional bowl line. Our ambitious goals for next year were also added. After that, what was required of the line was simple: We simply wanted to have the best and fastest line in the plant here – and that’s where MULTIPOND, our partner of many years, came into play bringing its project expertise.”

The line itself involves a bowl line located in the plant’s high-care section. The bowls are filled with various ready-to-eat salads consisting of a main ingredient, for example different leaf salads or cooked noodles and several salad toppings like shrimp, chicken, mozzarella, olives, pineapple, and mandarins right up to small pieces of beef or boiled egg. Depending on the recipe, the target weights are between 10 g and 150 g. General manager Hans Boshuizen comments: “In packaging products of this type, the market demand for bowls is steadily increasing. So, it became imperative to invest in an additional bowl line. Our ambitious goals for next year were also added. After that, what was required of the line was simple: We simply wanted to have the best and fastest line in the plant here – and that’s where MULTIPOND, our partner of many years, came into play bringing its project expertise.”

The entire line consists of six filling points total; three are automated and three require manual filling.

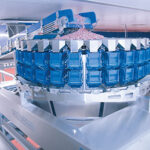

About the three weighing systems, an MP 14-3800/1250-H, 14-head multihead weigher for weighing the main ingredients and two MP 10-1000/400-H, 10-head weighers that fill the toppings are involved. The weighing systems were located above the ceiling, while the funnels were built directly into the ceiling. The final step, a 3-track product transfer system developed specifically for this application distributes the prepared servings into the bowls.

All product contact parts are precisely adjusted to production requirements and to the products being weighed to render the most perfect product flow possible. Once it has arrived at the weighing systems, the products are first conveyed to the prefeed hoppers by the radially positioned feed trays and then to the weigh hoppers underneath. Here, using the partial portions, a computer determines the combination which corresponds to the target weight to be achieved or is closest to it. After the actual weighing process, the precisely weighed servings are transferred via the outlet funnel by means of a timing hopper to the swiveling funnel which distributes the portions to the product transfer system. Maximum accuracy and availability are provided by the calibration systems integrated in each load cell, making completely automatic calibration possible even during production. The line runs with 40 bowls per minute total at a standard deviation of less than 1%.

All product contact parts are precisely adjusted to production requirements and to the products being weighed to render the most perfect product flow possible. Once it has arrived at the weighing systems, the products are first conveyed to the prefeed hoppers by the radially positioned feed trays and then to the weigh hoppers underneath. Here, using the partial portions, a computer determines the combination which corresponds to the target weight to be achieved or is closest to it. After the actual weighing process, the precisely weighed servings are transferred via the outlet funnel by means of a timing hopper to the swiveling funnel which distributes the portions to the product transfer system. Maximum accuracy and availability are provided by the calibration systems integrated in each load cell, making completely automatic calibration possible even during production. The line runs with 40 bowls per minute total at a standard deviation of less than 1%.

The three systems comply with the highest hygiene requirements in the salad sector. The weighers are operated by means of a user-friendly color touch screen monitor. Production manager Sam Mos comments: “Thanks to the simple user interface, our employees can operate the MULTIPOND weighers in the shortest amount of time, which for us is tremendously important. The reliability of the machines is terrific. “

The three systems comply with the highest hygiene requirements in the salad sector. The weighers are operated by means of a user-friendly color touch screen monitor. Production manager Sam Mos comments: “Thanks to the simple user interface, our employees can operate the MULTIPOND weighers in the shortest amount of time, which for us is tremendously important. The reliability of the machines is terrific. “

General manager Hans Boshuizen too is extremely satisfied with the results:

“If you consider all the factors like giveaway, reliability, spare part requirements and personnel costs, then the MULTIPOND systems pay for themselves in the shortest amount of time. A genuine partnership between the two companies has developed over the years as a result. Further joint projects are planned for the near future.