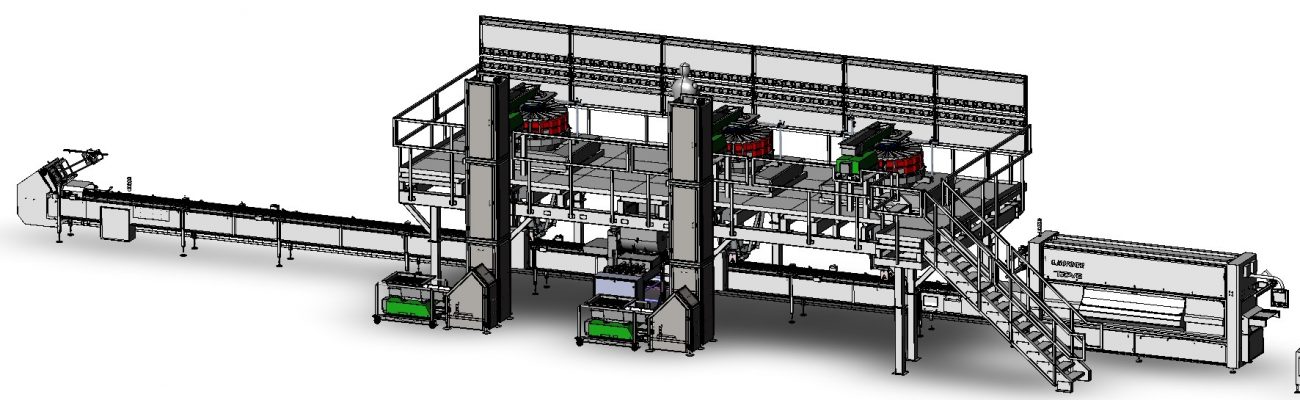

Ready Meal Line

Client Request:

- Client outgrew their existing plant and built a new state of the art green field production facility

- In doing so the client requested a high-speed line to produce up to 100 trays/min with the capability of 5 separate fills into their readymade meals

Objective:

- Provide a high-speed line that would provide 5 fills into 100 trays/min

Discovery:

- After consulting with tray sealing companies we determined that a dual lane conveyor would be required to reach the 100+ target speed

- Preliminary layouts revealed that the room was not large enough to accommodate multiple incline conveyors

- The client also required a checkweigher and sorting solution to distribute the trays into 3-4 lanes to optimize the freezer efficiency

Solution:

- Three Multipond scales filling pasta, protein and toppings with split outlets to accommodate the dual lane conveyor

- Due to space constraints, we designed and built custom vertical tippers to deliver the product to the scales

- Designed and fabricated the mezzanine to work around the tray line, support the scales and to provide access for cleaning

- Trays were check weighed with an Anritsu dual lane checkweigher and sorted into 3 or 4 lanes using our custom designed high-speed switch conveyor depending on the skew

- Integrated the process and provided local installation and service