MULTIPOND’s NEW 18 head weigher is the ideal solution for weighing small portions at high speed!

The 400 series multihead weigher has been extended to include a NEW high speed 18 head weigher. With a small footprint this machine is capable of speeds up to 300 packs per minute making it ideal for feeding a high-speed continuous motion GEA vertical bagger.

Best suited for small packs of confectionary, snacks, nuts, and cannabis, etc. The compact design has the benefits of MULTIPOND’s J-Series including IP69 sanitary construction, automatic calibration and new metal detector check feature providing automated and independent verification that your metal detector is operational.

FACTS

- Up to 300 weighing’s per minute in combination mode

- Up to 360 weighing per minute in dosing mode

- Portion weights from 0.5g to 100g (depending on bulk density/speed/accuracy)

- Optimized accuracy for the lowest weighs

- Automatic Calibration

- Compact, dust and water-repellent design

- Extremely compact design developed to cope with headroom restrictions

- Ideal for small target weights (mini bags, soup mixes, and dried ingredients)

- Combining, mixing, counting, and dosing applications

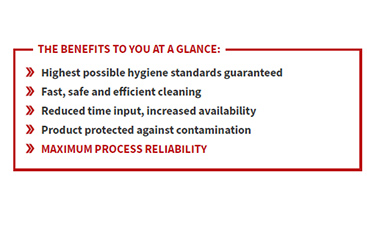

HYGIENE REDEFINED

Food manufacturing and processing is governed by strict specifications, standards, and guidelines. The experience and knowledge MULTIPOND have gathered over decades in the food industry is consistently transformed into technological innovations.

PROTECTION CLASS IP69

The weighing systems from MULTIPOND conform to IP69, a protection class that guarantees a water-proof machine design. Problem-free, quick, and simple cleaning by means of a high-pressure cleaner. MULTIPOND is the only manufacturer of multihead weighers to achieve this protection class without generating expensive overpressure in the machine.

METAL DETECTOR CHECK: PROCESS CONTROL AT THE HIGHEST LEVEL

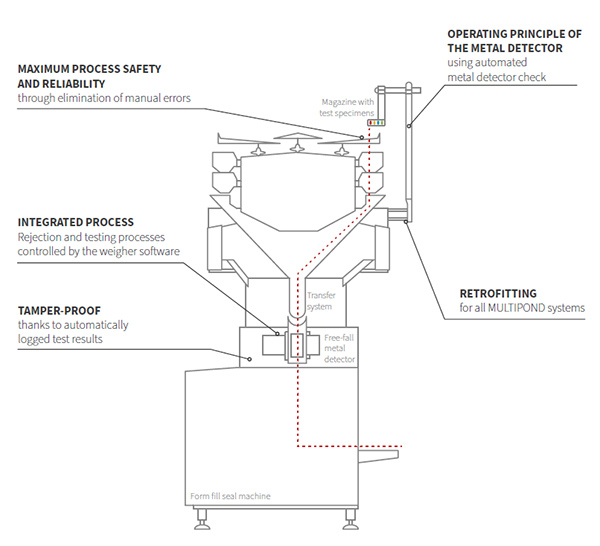

Process safety and quality play a key role in food production. It must be absolutely guaranteed no foreign bodies whatsoever find their way to the end customer. One way of detecting metallic foreign bodies in packaging is to use metal detectors at defined points in the process chain. To ensure these devices are functioning properly, MULTIPOND developed an automated metal detector check, a system integrated into the weigher.

How it works!

A magazine positioned above the weigher holds a defined number of test pieces, while the fill level is monitored by means of optical sensors. At predetermined (user selectable) intervals the actuating device automatically feeds the test piece into the product flow on top of the weigher, where it eventually passes through the metal detector and detection is monitored and logged by the Multipond.

The weigher software ensures tamper-proof logging of the dump and testing processes, and the data can be preported. The entire system meets common hygiene requirements and has an IP69 protection class rating.

Downtimes are reduced, costs saved, potential problems eliminated, processes simplified and made safer.

![]()

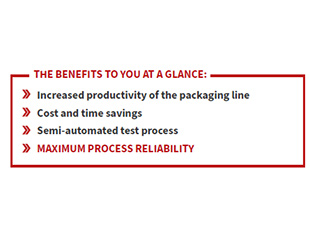

GEA Vertical SmartPacker  CX250-S features a low-drop design, which enables fast and compact filling and reduces damage of brittle products such as hard candy or crackers. The vertical packer is also equipped with an innovative, easy-to-use labelling system, improved product-in-seal detection and double-hinged doors for easy-access and maintenance.

CX250-S features a low-drop design, which enables fast and compact filling and reduces damage of brittle products such as hard candy or crackers. The vertical packer is also equipped with an innovative, easy-to-use labelling system, improved product-in-seal detection and double-hinged doors for easy-access and maintenance.

Dedicated design for high-speed packing

- Runs up to 250 bags/min, depending on specifications

- Low-drop between weigher and jaw head allows high speed and compact portion packing

- Avoids damaged products in pack thanks to machine design

- Bag enhancement options include labelling, printing, adding euro hole and re-closability

- Full integration with Multipond weigher including full HMI functionality

LEARN MORE about the GEA Vertical SmartPacker CX250-S