- Home

- About

- Equipment

- Projects

- Turnkey Project Solutions

- Application

- MULTIPOND – 18 head weigher

- High Accuracy Cannabis Solutions

- MULTIPOND – Fully Automated Weighing of Poultry Products

- Superior Turnkey Produce Lines

- Formost Fuji – Innovative Trayless Meat System

- Formost Fuji – Ground Meat Line

- Formost Fuji – Packaging Solutions

- MULTIPOND – Diced Ham

- MULTIPOND – Ready To Eat Salad Solution

- Anritsu Food Automation Inspection Technology

- Junapack – Pouch design guide for efficient operation

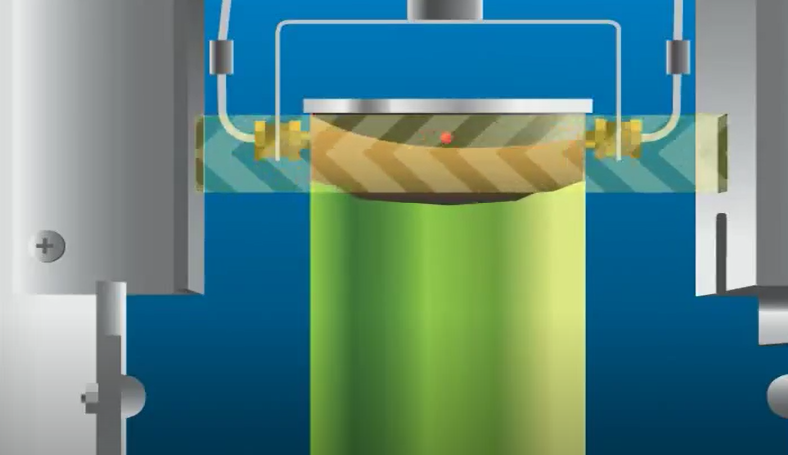

- GEA – Smart Sealing System

- Liftvrac Belt Conveyors

- Formost Fuji – Sustainability

- GEA SmartPacker TwinTube

- Services & Parts

- Mobile Demo

- Contact

Instagram page opens in new windowLinkedin page opens in new windowFacebook page opens in new windowYouTube page opens in new window

Instagram page opens in new windowLinkedin page opens in new windowFacebook page opens in new windowYouTube page opens in new window