No hassle, just packing GEA SmartPacker TwinTube. High-speed productivity.

With a combined production output of up to 500 bags per minute and a new modular design, the GEA SmartPacker TwinTube high-speed packing system brings big productivity benefits, more flexibility and operational efficiency with a small footprint.

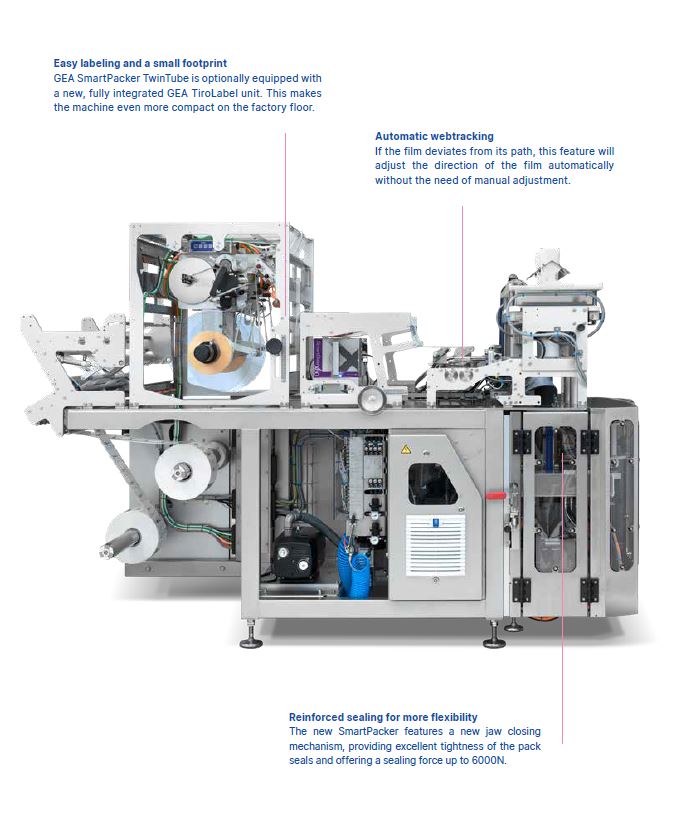

Intelligent automatic web tracking eliminates film deviations during production, without the need of manual adjustment. Operating with two parallel forming tubes, it achieves combined speeds of up to 500 bags per minute. Now, thanks to the Jumbo Roll for film reels (160 kg), you can also benefit from long production runs.

Reliability you can count on

- Over 98% uptime, proven in installations around the world

- Backed by GEA‘s years of experience in vertical packaging

- Consistent and accurate bag length, thanks to monitored film transport and jaw movement

- High seal force enabling gas-tight bags over a wide range of film material (optional)

Dedicated design for high-speed packing

- Low drop between weigher and jaw head allows high-speed and compact portion packing

- Innovative, open machine design allows easy access, visibility and efficient maintenance

- Automatic web tracking eliminates film deviations during production, without the need of manual adjustment

High efficiency with a small footprint

- Future-proof modular design allows easy installation of options or upgrades

- Space and cost savings through efficient use of factory space

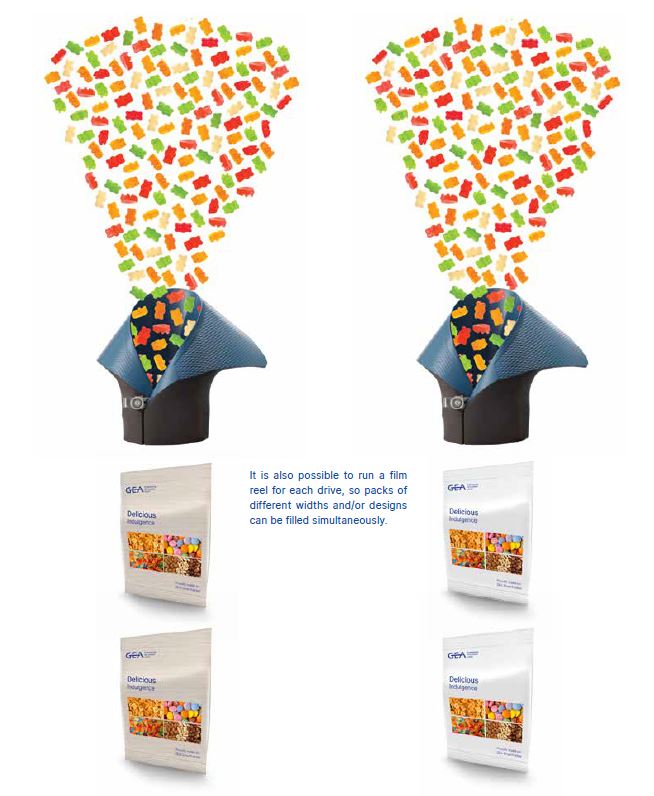

- Flexibility, thanks to the option to run different single reels per tube simultaneously

- Optional Jumbo Roll for film reels of up to 160 kg allows long production runs for high efficiency

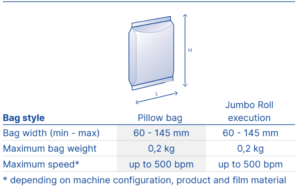

Machine specification:

• SmartPacker TwinTube

Equipment dimensions:

• 1547 x 1590 x 2755 mm

• 1547 x 1590 x 3550 mm

Jumbo Roll execution Application:

• Confectionery

The machine features an innovative open design with double-hinged doors for easy access. See-through panels provide maximum visibility of the sealing area. Full access and easy maintenance are made possible via the machine’s hinged front-plate to which the sealing arms and vertical seal are attached and which can be fully opened. This means that all items requiring maintenance can be easily accessed.

The machine features an innovative open design with double-hinged doors for easy access. See-through panels provide maximum visibility of the sealing area. Full access and easy maintenance are made possible via the machine’s hinged front-plate to which the sealing arms and vertical seal are attached and which can be fully opened. This means that all items requiring maintenance can be easily accessed.

The dedicated labeling unit delivers a speed of up to 180 labels per minute at a length of 150 mm and has a millimeter precision at labeling. The label roll has a quick-release operation, allowing it to be changed quickly with minimal loss of operational time.

Smart Solution from sustainable forests GEA worked in cooperation with Sappi, a market leader in innovative package barriers and sealable papers to develop a paper-based, vertical packaging solution for use with our GEA SmartPacker TwinTube. This is a new flexible solution that allows customers to choose a functional paper grade- based solution for their application and barrier requirements.