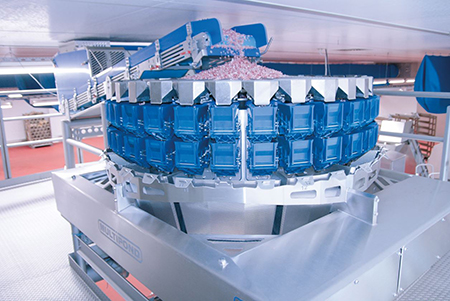

Diced ham producer goes for weighing technology from MULTIPOND

For the long-standing MULTIPOND customer meat and sausage products have been the focus for three generations. The company philosophy is: Quality, craftsmanship and innovation for the customers. “In Recent years, there has also been heightened consumer awareness about product safety, quality and hygiene”, says the Technical Manager of the ham cube manufacturer. And so more than ever before, the top priorities in the meat-processing industry are safety, quality and hygiene. Therefore, the company relies on the multiple-head weighers from MULTIPOND for good reason. Recently, an additional weighing system, type MP-30-1000-400-J, for weighing diced ham has been acquired for the factory.

The limiting room height of 4.50 m was the greatest challenge for this project. Every millimeter counted in the planning stage. The gap between system and ceiling is just a few millimeters. “This is very special equipment construction. From our previous experience, it was clear that only MULTIPOND can do this.”, explains the Technical Manager.

The limiting room height of 4.50 m was the greatest challenge for this project. Every millimeter counted in the planning stage. The gap between system and ceiling is just a few millimeters. “This is very special equipment construction. From our previous experience, it was clear that only MULTIPOND can do this.”, explains the Technical Manager.

Once the diced ham has arrived on the weigher, it is first conveyed to the prefeed hoppers by the radially positioned feed trays and then to the weigh hoppers underneath. Using the partial portions, a computer determines the combination that comes closest to the 125g target weight. All product contact parts are precisely adjusted to the production requirements and the properties of the diced ham in order to guarantee a smooth product flow. The weigher is controlled and operated using a convenient color touchscreen monitor. The fully automated calibration of the proprietary load cells ensures the highest accuracy and availability through the integrated calibration weight in each weighing cell. MULTIPOND is the only manufacturer of multihead weighers worldwide – who fully automatically, calibrate whilst running. The 30-head weigher is equipped with a 3-way outlet. A motor-driven timing hopper installed under each of the outlets transfers the portions to the downstream transfer system.

The gimbal-mounted transfer system with incorrect weight Reject was designed specifically for this application by Gröneweg represents the interface between weigher and packaging machine. Swivel hoppers distribute the weighed portions into the 6×3 format hopper. The subsequent, Rise and Fall 6×3 format Distribution unit ensures that the portions are transferred correctly into the trays of the downstream thermoforming machine and the sealing seams remain dry in the process.

The gimbal-mounted transfer system with incorrect weight Reject was designed specifically for this application by Gröneweg represents the interface between weigher and packaging machine. Swivel hoppers distribute the weighed portions into the 6×3 format hopper. The subsequent, Rise and Fall 6×3 format Distribution unit ensures that the portions are transferred correctly into the trays of the downstream thermoforming machine and the sealing seams remain dry in the process.

The entire system was designed for an output of 12 times 18 packages per minute. The target weights of the end packing are from 75g to 125g. The mean value achieved, a decisive criterion for the give-away, corresponds exactly to the target weight. The standard deviation with 125g of target weight is approx. 1.3g.

The hygienic design of the weigher is the basis for fast and simple cleaning. All J-Generation multihead weighers have protection class IP69 as standard. The weigher undergoes daily a complete wet clean. During this process, the weigher is literally placed “under water”. The quick and tool-free removal of product contact parts effectively reduces the system’s downtime for cleaning and maintenance work to an absolute minimum. A wash wall from Gröneweg additionally installed on the platform also simplifies the cleaning process many times over.

Drawing on its long-standing experience of weighing the most difficult products, MULTIPOND was at our side offering a wealth of knowledge, says the Technical Manager. Our extremely positive experience with MULTIPOND in the past was yet another key decision factor for the customer. The weigher is now the fifth multihead weigher from MULTIPOND. All MULTIPOND systems run almost fault-free and are completely reliable. The excellent on-site service was another decisive plus point for MULTIPOND.

MULTIPOND has been an owner-managed German company since the very beginning. Drawing on more than 70 years’ experience in industrial weighing technology, we are a pioneer in this sector. Our success is based on the high quality and excellent technical standard of our weighing systems. We consciously commit to a high level of vertical integration, as well as production exclusively in Germany. Customer focus has become our corporate maxim. A team of more than 250 employees commits worldwide to offer our customers from the food and non-food sectors optimized, unique solutions tailored exactly to their requirements at all times. Sales, project planning and service are handled by the headquarters in Germany, by the four subsidiaries in France, the Netherlands, UK and the USA, and by a worldwide network of agents.