Abbey Equipment Solutions is a Canadian company with the expertise and experience to deliver highly flexible equipment to automate your production line from the incoming raw materials to final packaging.

With their diverse line-up of equipment options, they provide their customers with fully integrated solutions all supported by their local service team. Abbey Equipment Solutions’ objective when embarking on a new project is to ensure they are providing innovative, flexible, and cost-effective options from full lines to single machines.

Processing

For all your processing needs TURATTI, from Prep Tables, Grading/Sorting, Cutting/Dicing/Spiralizing, Peeling, Weighing/Mixing, Infusion, Blanching, Cooling, Washing/Sanitizing and Drying.

K Series Transversal Slicer.

The family of transverse cutters are suitable for cutting lettuce and different types of vegetables into slices or strips, changing the thickness of the cut with a simple speed adjustment or replacement of the cutting wheel.

Main Features:

-

High flexibility and possibility to adjust the speed of the conveyor belt

-

Large selection of cutting thicknesses with continuous operation

HERA Universal Multi-Cutting Slicer

This versatile solution is designed for different types of cuts (cubes, sticks or slices) for a wide variety of vegetables and fruits (carrots, potatoes, cucumbers, melon, etc.). The three cutting heads allow flexibility in size and shape.

Main Features:

-

High cut quality and uniformity

-

Wide selection of cutting thicknesses

-

Continuous operation

-

Blades and components durable/high quality

VENEZIA Blowing Washer

This washing machine adapts to different production volumes and takes advantage of the gentle action of air bubbles to ensure an excellent result while preserving the integrity of the product. Suitable for baby leaves, lettuce, fruit, vegetables, and mushrooms, etc.

Main Features:

-

Suitable for floating and non-floating products

-

Adjustable intensity of water jets and aeration

-

Self-cleaning water filter

-

Monofilament extraction belt

-

PLC controlled with “touch screen”

-

Available with insect drum

-

Customizable

-

Sanitizing and/or rinsing

Dewatering, Drying Solutions

These systems continuously remove water from the surface of fresh fruits and vegetables, limiting the mechanical stresses on the product. They are often used upstream of the drying tunnel and are offered in different solutions based on the customer’s needs.

Main Features:

-

It carries out the draining with beaters, extraction of the water under vacuum and the removal of the product from the belt with blown air

-

Maximum flexibility for a wide variety of products and applications

-

Ideal for very fragile and delicate products

-

Designed and manufactured in compliance with sanitation principles

VORTEX Automatic Electric Spin Dryer

This centrifuge is one of Turatti’s iconic models because of its innovative technology. It is designed to remove water quickly and effectively from the surface of the product after washing while respecting the most delicate of products. Its effectiveness, compact design, and the different capabilities available, makes this machine very flexible.

Main Features:

-

Drying of very delicate and fragile products, whether in leaf or not

-

High quality drying level

-

Sanitary design for quick cleaning

-

Fully automatic operation with recipe control of machine parameters

ARCTIC-WIND Hybrid Cooling Tunnel

Ideal for greenhouse operations this Hybrid Cooling Tunnel is specially designed to insure maximum product temperature (1/2°C) at the exit with minimum running costs. The main advantage of the ArcticWind model is it can operate with cold air, with nitrogen or with both. It consists of one cooling section installed in the tunnel frame and is powered with glycol.

Main Features:

-

Shortening the cooling time

-

Excellent control of the product temperature

-

Reduces cooling costs

-

Easy access for sanitation and maintenance

Inspection of Raw Material

RAYTEC VISION optical sorting machines remove foreign bodies, mold, and poor-quality product from the line.

The CURIOSITY is the first optical sorting machine born to achieve the totally hygienic compliance according to the EHEDG guidelines. This sorting machine combines innovation, essential design, and latest vision technology, it perfectly meets the needs of safety and quality control, hygienic operation, easy and quick sanitation.

Main Features:

-

Double-Chlorophyl technology

-

Pulsed LED technology for optimum performance, flexibility, and low cost of ownership

-

Up to ten frequencies including red, green, blue, yellow, near infrared and chlorophyll can be combined to inspect any product for greater flexibility

-

Automatic capture of images and production data for post-production analysis

Conveying

The LIFTVRAC conveyor is a great alternative solution replacing other existing lifting systems on the market such as cleat belts, screws, vacuum system, and bucket elevators.

Main Features:

-

Gentle product handling

-

Elevates product without flights

Scraper at the discharge eliminating waste -

Modulates product and provides a controlled product flow to a Multihead weigher

-

Easy access for sanitation and maintenance

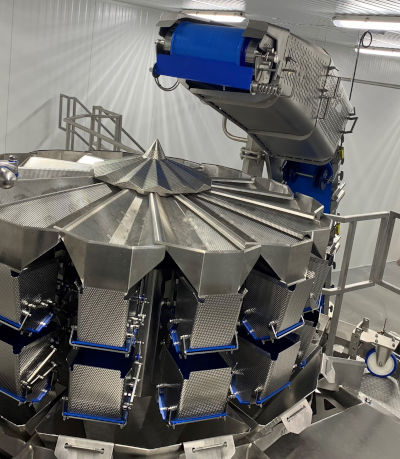

WEIGHING & FILLING

MULTIPOND’s industry leading performance, accuracy, and reliability characterizes their weighing systems.

MULTIPOND’s J-Series combination weigher for leafy products include motorized rotary cone, patented stepped profile feed trays and ARGUS 3D camera providing hands-off consistent distribution of the product into the cone resulting in optimum speed and weight accuracy.

Main Features:

-

ARGUS 3D Camera for precise infeed control from the LIFTVRAC conveyor to the Multipond weigher

-

Motorized rotary distribution cone is programmable and spins to feed the product where it’s needed on the weigher

-

Patented surfaces such as “stepped profile” aid the product flow in a way that dimpled surfaces simply cannot

-

Standard IP69K construction

-

Automatic calibration and feed control

Bowl & Clam Shell Filling

The MULTIPOND transfer system allows for simulaneous filling of 1, 2 or 4 trays dependin on the required speed.

Main Features:

-

Adaptable for different tray/bowl sizes

-

Tool-less format change

-

Servo motor controlled with integrated

product tamping -

Integrated controls with the Multipond

weigher -

Easy access for sanitation and

maintenance

BAGGING

GEA’s Vertical Flow Packaging Solutions set the standards for reliability and performance with proven accuracy of greater than 98%

The GEA SmartPacker CX400 handles a wide range of packaging types featuring its advanced sealing technologies – SmartSeal and UltraSonic Sealing.

Main Features:

-

Fast changeover of bag formats and film types in less than 5 minutes

-

Reproducible settings using recipe management

-

Easy-access design allows fast film changeover

-

Low maintenance costs & limited wear parts

-

Gas flushing capabilities

-

Hygienic solution

INSPECTION OF FINAL PRODUCT

Setting the standard in X-Ray performance

ANRITSU’s SSV checkweigher, XR75 X-Ray and/or Metal Detector can be combined providing outstanding weighing accuracy and product inspection.

Main Features:

-

Industry leading performance

-

Low TCO – Advanced Long Life (A.L.L) technology up to 300% longer tube & detector life

-

Diverse product line – packaged, bulk, cased product/

Combination, Checkweigher and Metal Detector coupled with an integrated Reject System to inspect the final product.

Main Features:

-

Smallest footprint in the industry

-

Detection of the smallest contaminants

-

Various combinations of units to meet your requirements

MECHANICAL SOLUTIONS, LINE INTEGRATION & SERVICE

Mechanical Solutions ranges from platforms, conveyors with a variety of styles/capacities, tippers, wash racks and walls, plus a wide range of custom fabrication options. All of which are coupled with an additional understanding of clean design, ease of maintenance, sanitation, and methodology of working with different raw materials, which flow seamlessly into your HACCP programs.

Abbey Equipment Solutions Canadian based service team provides ongoing accessible technical support throughout the whole process from, testing, training, and installation to ensure customer satisfaction. With our various programs and a focus on service & support we can guarantee a heightened level of performance and up-time throughout the life of the equipment.