d’Arta has been working with GEA packaging machines for years "GEA supports us in working more efficiently and sustainably".

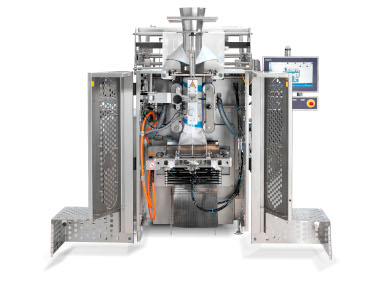

As a global player in the development, processing and marketing of fresh frozen products, the Belgian company d’Arta must be able to rely completely on its machinery. For years, the vertical packaging machines by GEA have ensured that d’Arta can work efficiently and quickly. “Our capacity has increased by at least fifty per cent since we started using these vertical packers.”

Jean-Pierre founded d’Arta in 1988. The Belgian family business has grown considerably over the years and today employs more than nine hundred people. The fresh frozen products such as vegetables, fruit, herbs, and ready-to-eat side dishes are exported to more than a hundred countries.

“We have been utilising GEA’s vertical packaging machines for years. Having used the first, second, third and fourth generation, we are currently working with the fifth generation. What I like, is that every time small technical improvements are made to the machine, the controls remain virtually unchanged, meaning our staff don’t require continual retraining. It is and will always be a GEA-machine, which, after an update, is even better suited to our needs.”

The new GEA Smart Sealing System uses special metal tapes in the sealing area and eliminates the need to replace the previously used Teflon tape on the heated sealing jaws after just a few hours. This offers many advantages: Maximizing productivity, reducing downtime, lowering the total cost of ownership (TCO) and improving package quality.

The new GEA Smart Sealing System uses special metal tapes in the sealing area and eliminates the need to replace the previously used Teflon tape on the heated sealing jaws after just a few hours. This offers many advantages: Maximizing productivity, reducing downtime, lowering the total cost of ownership (TCO) and improving package quality.

Over the years, GEA has ensured that a film change takes place quickly. “At GEA, they understand what our challenges and priorities are: production must be continuous. As one minute of downtime means a capacity loss of no less than a hundred kilos. There’s no coming back from that. Since we have been using GEA packers, our capacity has increased by at least fifty per cent.”

Previously, the heated jaws of the traditional sealing systems on vertical packing machines were commonly protected by Teflon tape to prevent sticking when running PE films. As a precautionary step, the tape would be replaced at the end of every eight-hour shift, which meant that standby sealing jaws would be used during the changeover after around 40,000 bags. The new system uses metallic strips with a non-stick, PFAS-free (Polyfluoroalkyl Substances) coating. This system can continuously seal up to one million bags reliably without changing the sealing strips.

Work more sustainably

The GEA Smart Sealing System is designed for pillow and gusset bags packed with frozen vegetables, fruits, potato products, meat, meat alternatives, fish, and seafood. Though initially developed for use with PE mono materials, the GEA Smart Sealing System can also be used with all widely used laminates, including recyclable material structures such as BOPE, MDOPE, PP-based laminates and paper laminates.

Together, GEA and d’Arta think about ways to work more sustainably. “In this day and age there is a lot of focus on the climate. That’s why we are exploring the possibilities of replacing PE film, a widely used packaging material, with a more sustainable alternative. We are currently testing a type of packaging made of paper. Important questions are whether we can package our products with this material just as quickly and without loss of capacity. The robustness of the packaging is also important: we obviously don’t want bags of peas bursting open in the supermarket. Having performed various tests, we have ascertained that the vertical packer is certainly not the bottleneck in this innovation process.”

The Smart Sealing System provides more reliable sealing of the bag with the incorporated product in seal detection system. Eliminating the possibility of open packages while also preventing sealing of the bag when food is detected in the seal area. Package leaks and damage to the knife, which cuts the single pouches after closing, are thus avoided, as it does not get in contact with the product which is fouling the seal area. In tests, knives have also handled up to one million bags successfully without having to be replaced. The result: lower costs and improved productivity.

Innovating together

d’Arta opts for machines with a long service life. “The fewer technical problems there are, the more I can concentrate on new challenges within our company,” says De Backere. “Technology in our industry doesn’t stand still, which is why we are always innovating. GEA shares our innovative character. At the beginning of my career, the engineers at GEA came up with an interesting question: ‘What can we do to make the machine even more effective for you?’ Of course, we are always open to improvements. GEA has a strong engineering department. We want to stay one step ahead of the game in terms of integrating technical changes that help us move forward. If all our suppliers acted this way, we would be very happy! GEA is very committed to our company. We can always rely on them.”

GEA has additionally increased the pressure applied by the Smart Sealing System to each seal and has reduced the cooling time of the produced seal for each cycle. The result is a faster running speed and a 20% increase in machine output. All in all, overall equipment efficiency (OEE), sealing consistency and packaging quality are increased.