Checkweighing Solution For Aerosol Cans

Client Request:

The customer required a new solution that would reduce maintenance costs and downtime needed for repairs of the chain. They also required a system that was more accurate.

The customer was struggling with high maintenance costs and time-consuming repairs of a chain type checkweigher. In addition, checkweighing accuracy was not very good and it degraded as the checkweigher chain was wearing out.

Objective:

The objective was to provide a more accurate solution with a lower cost of ownership.

Discovery:

The reason for using the sophisticated chain type of checkweigher was the properties of the product itself – tall and narrow aerosol cans tend to tip at transfers between conveyors.

Solution:

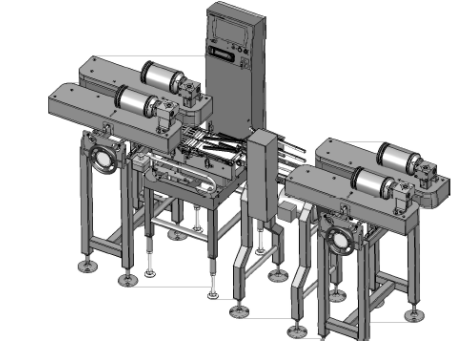

Our solution was to provide a turnkey checkweigher replacement which included the following equipment.

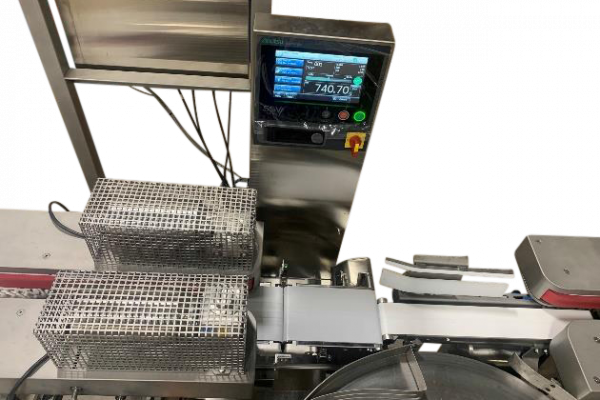

- Anritsu Flat Belt Checkweigher Suitable for Washdown Environment

- Custom Reject System for Aerosol Cans with a Catch Box

- Custom Side Belt Systems for Smooth Transfer of Product