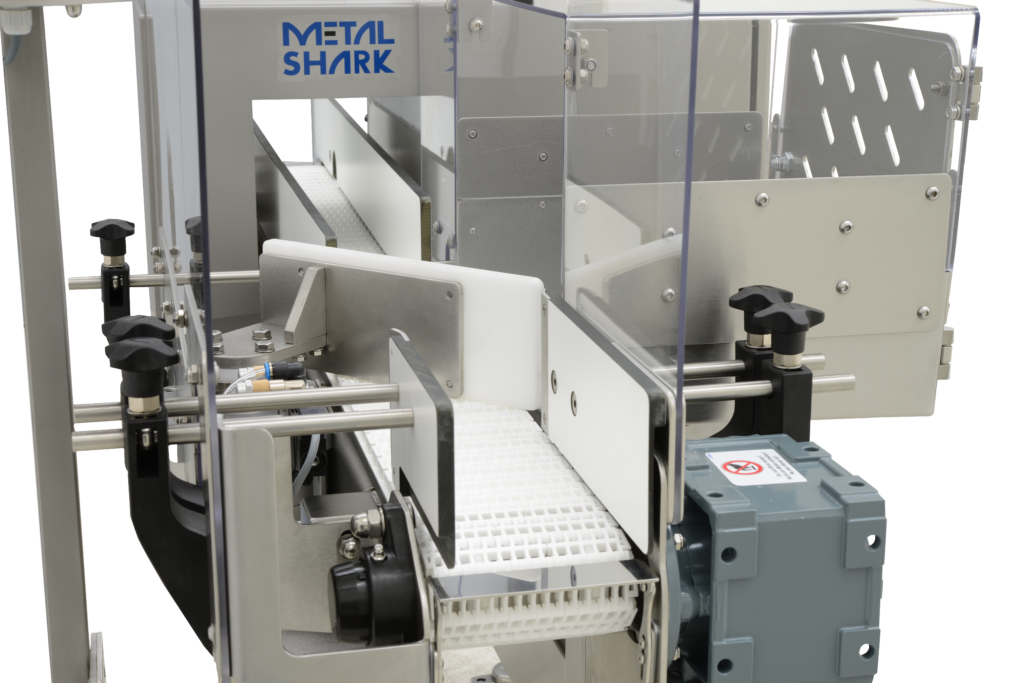

Conveyor Feed

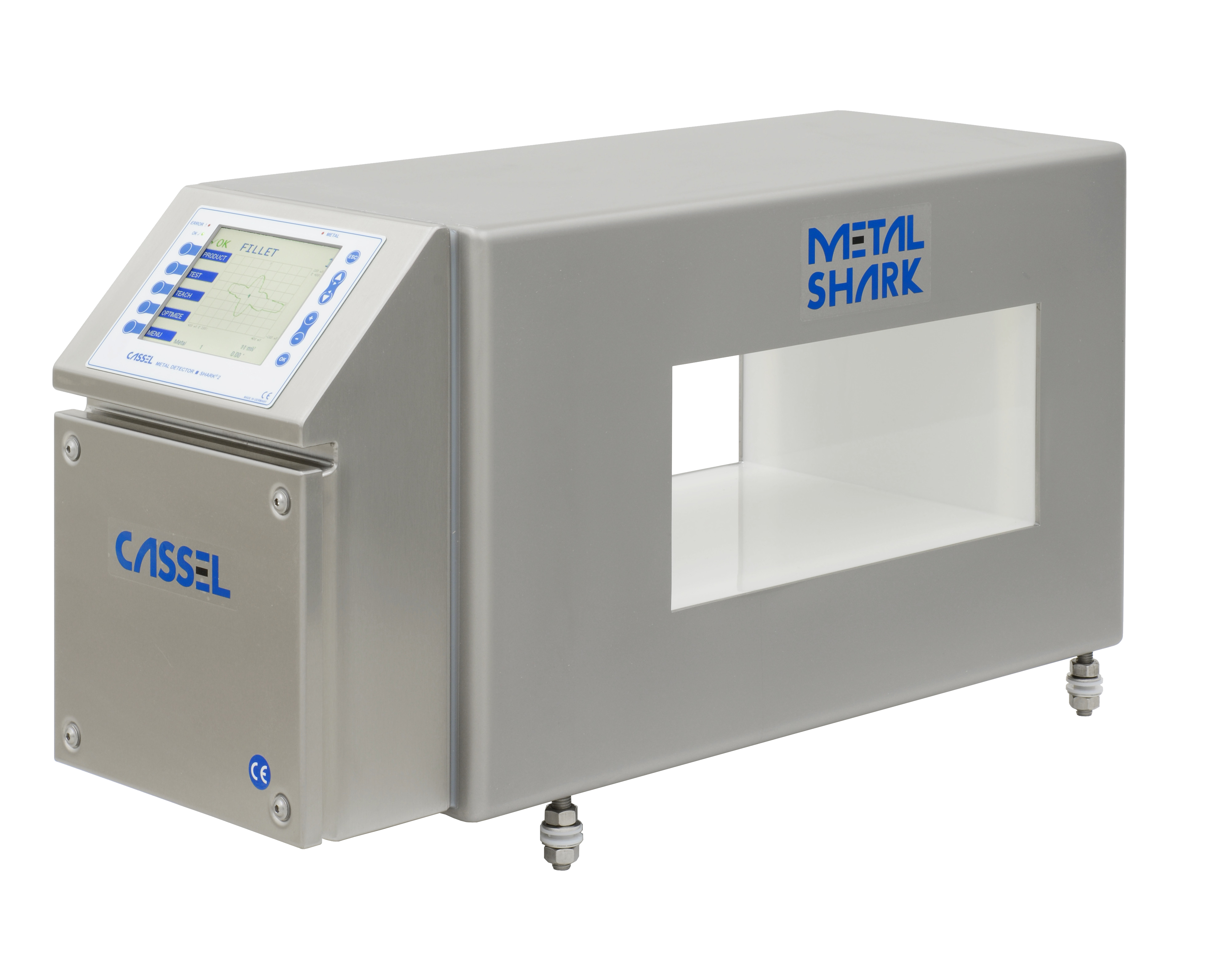

CASSEL METAL SHARK® BD is used free-standing or combined with conveyor belts or chutes. Using 3D detection technology, it detects the smallest magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminum etc.) precisely and reliably even under difficult conditions.

The robust, closed stainless steel housing is easy to clean and therefore ideally suited to the food industry.

All CASSEL metal detectors are custom-made and can be individually adapted to the requirements of the respective production environment.

- Maximum detection performance with the highest reliability in the entire detection area due to 4-quadrant technology.

- Stable against temperature or product changes through 3D detection

- Storage spaces for up to 250 products

- Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

- Cyclical function monitoring with Performance Validation System (PVS)

Advantages

- Reliably detects metals in packaged and unpackaged goods on conveyor belts

- Very high sensitivity in dry, moist, salty, or frozen goods

- Easy setup and intuitive operation due to auto-calibration and wizard guidance

- Maintenance-free design with automatic and continuous calibration of detector coils

- Compliant with food safety standards (IFS Food, HACCP, BRC*)

CASSEL’s unique 4-Quadrant-Technology has evolved to the 3rd dimension. The MultiPhase and BOOST FACTOR technologies add multi-phase measurement and signal amplifying factors to this established technology and thus create 3-dimensional signal models of your product’s signatures – as unique as a fingerprint.

- BOOST FACTOR: Up to 50% more accuracy, the SHARK detects stain-less steel up to 1 mm smaller compared to conventional detectors.

- MultiPhase: Continuous adjustment to changing conditions for even more stability.

The METAL SHARK® can easily cope with frozen or heated products, changing product orientations or temperatures as well as cooled, heated or humid environments.

CASSEL Inspection’s Shark MultiSense metal detector delivers complete protection from metal contaminants. The MultiSense metal detector’s high sensitivity, automated operation, and intelligent signal processing are designed to reduce downtime with automated set-up and auto-learn capabilities, offer an improved probability of detection in even the most challenging applications, and eliminate failed audits and false rejects. Multi-dimensional detection and statistical learning capabilities deliver greater accuracy to your food safety systems.

- Improves food safety by detecting up to 50% smaller metal fragments in difficult high product effect applications

- Advanced hardware and software features support due diligence to meet a wide range of global food safety standards

- Productivity is enhanced via graphical on-line monitoring with quick adjustment reducing annoying false rejects to near zero

- An all new graphical user interface guides the user along the way making high performance set-up easy to achieve, and ensures the ability to maintain effective, reliable operation 24×7

- Innovative multi frequency technology builds on our legacy of customer focused R&D in metal detection

Industries

- Food processing applications

- Meat

- Seafood

- Frozen goods

- Chocolate

- Wet and salty foods

- High mineral content foods

Bottle Conveyor

Conveyor for bags

Conveyor with reject bin

Horizontal to inclining with retractable reject

Inclining reject collect tray

Retractable reject

Conveyor with fliparm

Transversal pusher TP with intralox belt

Conveyor with siderails