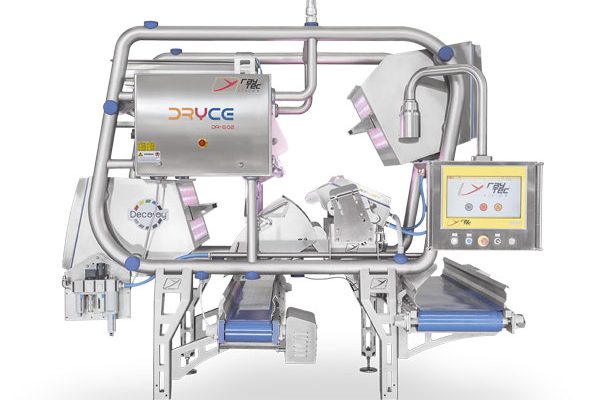

Gravity Sorter

Dryce is an optical sorting machine with high resolution cameras that examine the product using the “free fall double side view” system which analyzes 100% of the surface of each product. The system is specially designed to sort Dried and Frozen food products.

- High production capacity. Enables selection of large quantities of product in little time

- Significant labour savings (up to 100% according to application)

- High levels of Quality and Safety of products selected not achievable through labour

- Detection in real time of qualitative and quantitative data of raw material

- Automatic capture of images of rejected products and their filing for post-production analysis

- Constant selection over time, also over 3 work shifts

- Maintenance of high standards of hygiene thanks to the original ultra-clean design

- Low maintenance costs

- User-friendly software for easy use and programming

Dryce can dispose of

- Colour defects

- Rotten produce

- Foreign bodies

Dryce is available in three versions:

|

DR-602:

|

DR-1202:

|

DR-1802:

|

All models can be equipped with 3Way ejection system and can have two reject systems on board to differentiate unusable produce from second quality.

Raynbow is a high-resolution optical sensor sorter that analyzes 100% of the surface of each product thanks to the “double vision on the fly” system.

Raynbow is able to discard color defects, deteriorated products and foreign bodies even of the same color as the good product. The product is fed by means of a conveyor belt that stabilizes the product before viewing.

Raynbow can have the vane or air reject system. It can have only one ejection system, or, in 3Way mode, it can have two reject systems that differentiate unusable defects from defects considered second choice products.

- High production capacity

- Significant reduction in labour force

- Real-time detection

- Automatic image capture

- Constant selection over time

- Low maintenance costs

- User friendly software

INGENUITY is a double-vision sensor sorter. It is equipped with Visible Color and NIR technology (Near Infra Red).

The system can detect organic or inorganic foreign bodies (including completely black), rotten products and color defects.

Thanks to the 100 channels configuration, INGENUITY allows a capacity up to 80 t/h, for large agro and industrial production.

The machine is available in a 2WAY configuration, and the ejection system is by mechanical fingers in a special high-resistance and anti-abrasion material.

- High production capacity

- Low maintenance

- Real-time detection

- Automatic capture of images

- Constant selection over time

- Low maintenance costs

- User friendly software