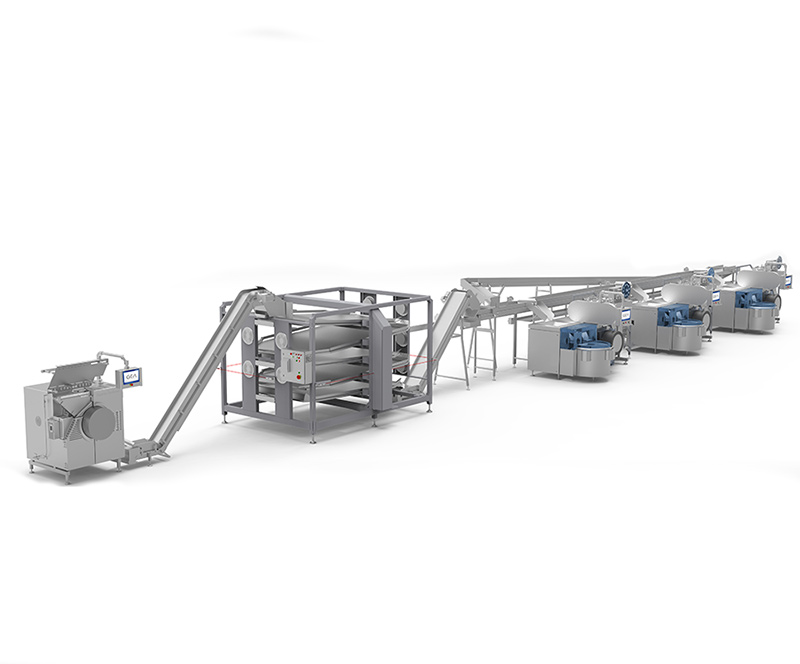

These lines include our renowned machines such as the GEA Aquarius FlexFormer machines with best of its class GEA Aquarius PopCooler range for cooling. For highest performance and output our reliable wrapping machines the GEA Aquarius BunchWrapper and/or TwistWrapper machines can be included in this solution. To complete the line solution, we can offer our PopFeeder system which automatically feeds the lollipops towards the wrapping machines.

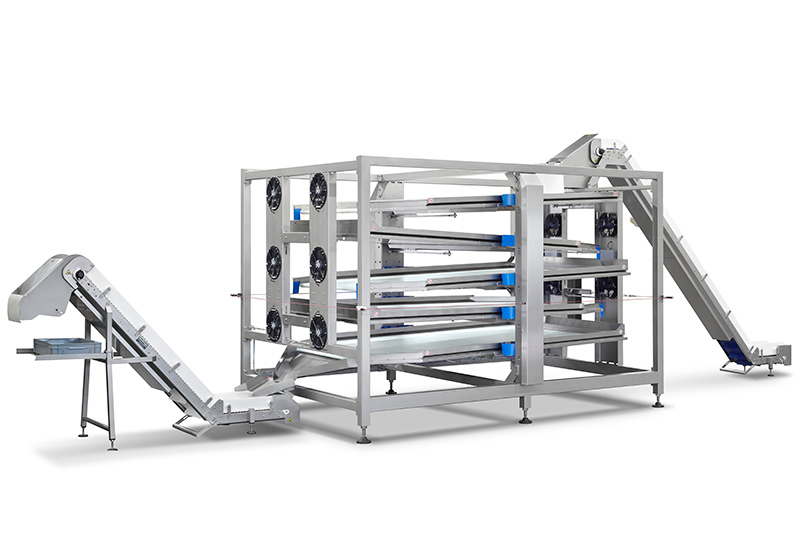

GEA AQUARIUS FLEXFORMER & POPCOOLER

The FlexFormer is very flexible, quick changeover between sizes or shapes of lollipops are possible as well as easy adjustment for different stick lengths. Whatever shape you would like to make, whether ball, three-dimensional, GEA Aquarius has with the FlexFormer range the right machine for the job. Also available in faster speeds with the XHC (Extra High Capacity) series (GEA Aquarius FlexFormer XHC extra high capacity) or the startup option which is configured to appeal to young companies and smaller operations. (GEA Aquarius FlexFormer Start Up)

Our Aquarius forming machines are known for the highest quality ball and 3D lollipop shapes to ensure after forming this high quality lollipop, the lollipops are transported directly towards the PopCooler B SC or HC to ensure that the perfectly formed lollipop will have no deformation or lose any design detail.

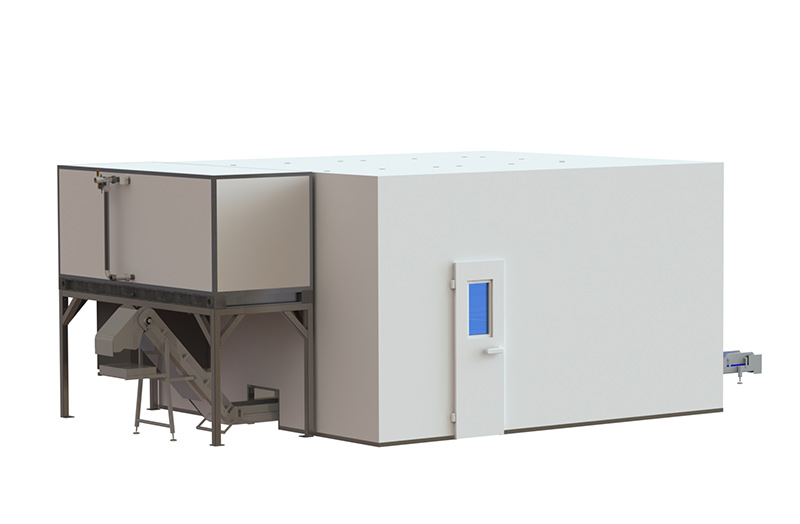

PopCooler B HC & eNCLOSURE

For more information visit – GEA Aquarius PopCooler B

BunchWrapper 600 – 800 with Label on stick unit

Main Application – Bunchwrap style: solid or center filled hard candy lollipops as well as round 3D ball lollipops with a diameter of 18 up to 35 mm.

Over 20 years our GEA Aquarius BunchWrapper series ensures hermetically sealed lollipop wrapping with optimal productivity and fast changeovers for the confectionery market. Offering flexibility in further continuous packaging in bags or containers or tools for marketing purposes.

This continuous lollipop wrapping machine is now optimized and perfectly fit to reach your optimal wrapping output further when frequently changing over to another diameter lollipop, ensuring your expectations further in terms of reliability and ease of use as it is easy to operate with a machine efficiency up to 94%. With this optimization you will benefit of fast and smooth changing over to a different diameter lollipop with the simplicity of this change over for your operators. Doing so without compromising on efficiency and reach the ultimate output with each diameter lollipop you want to wrap.

Key benefits:

- Increased output – when frequently changing over to another diameter and size lollipop

- Simplicity – automatic configuration ensures fast, efficient, and safe change over

- Future proof design – no mechanical changes needed. The machine is already prepared for future change overs to different diameter lollipops

- BunchWrapper 600 upgradeable to 800 when needing to add capacit

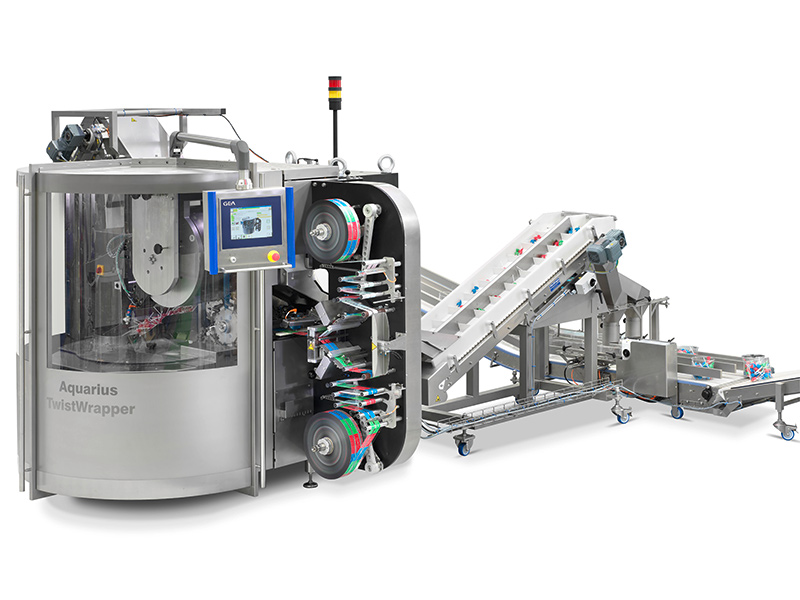

TwistWrapper 600 – 800 – 1000 CAPACITY

Our consumers demand lollipops which are easy to open and have an outstanding shelf life.

We therefore developed on our TwistWrapper series the longitudinal seal, so you can prolong the shelf life of your premium quality ball lollipops, with the simplicity to open the wrapping for maximum convenience with an easy tear slit to wrap and open the lollipops with a twist.

Main Application – TwistWrap style: solid or center filled hard candy lollipops as well as round 3D shaped lollipops such as a soccer ball shape with a diameter of 16 up to 35 mm.

The GEA Aquarius TwistWrapper is a continuous wrapping machine which Handles film reels up to 420 mm diameter. It achieves the highest speeds found in the market through smooth film handling, precise cutting, and automatic feeding. The machine ensures less film costs per lollipop than with an intermittent wrapping machine. The machine is suitable for heat-sealable wrapping materials such as cellophane, polypropylene, and laminates.

Ease of use:

- Splicing unit for automatic film changes without standstill wrapping machine

- Reproducible settings using recipe management in touchscreen

- Easy change over set to change over easily to other weight or diameter lollipop

Reliable cost-effective wrapping:

- Up to 30% less usage of film than with a bunchwrap stye..

- Ensured consistent sealing quality around the stick via patented induction heating

Flexibility you need:

- Easy to integrate in a line solution with PopFeeder systems and container filling systems

- TwistWrapper 600 and 800 are upgradeable when needing to add capacity

Easy to maintain:

- Closed machine housing for easy cleaning and reduction usage of wear and tear parts as these are protected against entry of dust.

- Working and control components are placed in stainless steel compartments

Longitudinal seal

- This hermetical seal ensures that moisture will not enter the wrapping easily which prolongs the shelf life of your lollipops, particularly in areas with high atmospheric humidity. With the Tear slit the Longitudinal seal is extremely easy to open. To make this seal you need to use film material, polypropylene with an inner and outer side sealing layer. You can wrap lollipops from 16 up to 30 mm at speeds from 600 up to 800 lollipops per minute.

For more information visit – GEA Aquarius TwistWrapper

Popfeeder System for BunchWrapper or TwistWrapper

Popfeeder System for Bunchwrapper or Twistwrapper

- Can be delivered with a return feed conveyor belt

- Can be delivered with a transporting belt to feed automatically further to a SmartPacker to pack lollipops in a pillow blockbottom bag.

PopFeeder 1: feeds the lollipops towards 1 bunchwrapper or twistwrapper

PopFeeder 2 or 3: feeds the lollipop towards 2 or 3 BunchWrapper or TwistWrappers which stand in line.