Raytec sorters remove product defects and foreign materials based on Infrared, Chlorophyll, Translucency, Color, Shape. Raytec offers a wide range of sensor-based sorters and camera-based sorters.

Opportunity it an optical food sorter that uses artificial intelligence and 360-degree product quality control. Thanks to the roller belt that allows products to rotate and matrix cameras to capture multiple frames of the rolling product, it performs a real-time image of each product, on each side, thus enabling us to identify even the slightest defect and presence of decay/mold in any part of the product. The great advantage of artificial intelligence is that the machine learns with the acquisition of many images and easily adapts to the growing needs of quality control.

With its compact design and ability to communicate with other machines, OPPORTUNITY can be easily placed within processing lines to contribute to complete production automation.

Curiosity is the first optical sorting machine born to achieve the totally hygienic compliance according to the EHEDG guidelines. This sorting machine combines innovation, essential design and latest vision technology, it perfectly meets the needs of safety and quality control, hygienic operation, easy and quick sanitation.

Guided by our powerful UNYCO software, Curiosity can detect all the defects you are looking to reject, while caring for the good part.

A vibratory shaker built in the machine conveys the product to a vertical chute ensuring a consistent trajectory.

Curiosity is available in three versions:

CY-600:

| CY-1200:

| CY-1800:

|

- High production capacity. Enables selection of large quantities of product in little time

- Significant labour savings (up to 100% according to application)

- High levels of Quality and Safety of products selected not achievable through labour

- Detection in real time of qualitative and quantitative data of raw material analysed

- Automatic capture of images of rejected products and their filing for post-production analysis

- Constant selection over time, also over 3 work shifts

- Maintenance of high standards of hygiene thanks to the original totally hygienic design

- Low maintenance costs

- User-friendly software for easy use and programming

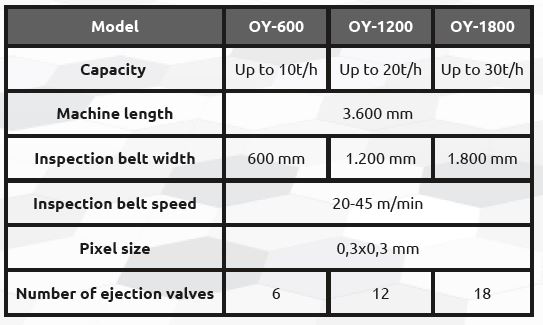

Discovery/Spray can dispose of colour defects, marked produce and foreign bodies also the same colour as the good product. The product is fed on the inspection belt used to stabilise the product so it doesn’t roll off. The inspection zone is clearly separated from the ejection zone to avoid product sprays which can prejudice selection over time.

- High production capacity. Enables selection of large quantities of product in little time

- Significant labour savings (up to 100% according to application)

- High levels of Quality and Safety of products selected not achievable through labour

- Detection in real time of qualitative and quantitative data of raw material analysed

- Automatic capture of images of rejected products and their filing for post-production analysis

- Constant selection over time, also over 3 work shifts

- Low maintenance costs

- User-friendly for easy use and programming