Poultry processor goes for weighing technology from MULTIPOND

The long-established poultry-breeding company KG Group is one of Lithuania’s highest-tech and economically strong production associations in Lithuania. Their philosophy of tradition, perfected experience, high working standards, as well as quality and innovation in production technology. The meat is supplied exclusively from its own poultry farms. Over 9,000 tons of meat are packaged every month, around half of which is exported abroad.

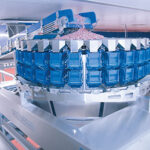

For good reason, then, Valdas Keršys, Maintenance Manager, decided on MULTIPOND for the multihead weighers. Two types, the MP-14-7100-2500-H-UL systems and a the MP-14-3800-2500-H-UL weigher were purchased for the factory in Vilnius for the fully-automated weighing of various poultry products.

For good reason, then, Valdas Keršys, Maintenance Manager, decided on MULTIPOND for the multihead weighers. Two types, the MP-14-7100-2500-H-UL systems and a the MP-14-3800-2500-H-UL weigher were purchased for the factory in Vilnius for the fully-automated weighing of various poultry products.

The project is unique in that each line has been converted with a different packaging machine to be able to filled into bags, trays and thermoformed packages.

The poultry products are fed to the three weighing systems via special spiked conveyors. Once on the weigher, the poultry meat is first conveyed to the prefeed hoppers via the radially positioned feed trays and then to the weigh hoppers below. Another key performance criteria was the use of Multipond’s patented “stepped” surface profile on the distribution cone and feed trays. This effective yet simple solution permits a straightforward and controlled conveying of the most adherent products, while maximizing careful product handling.

Using the partial portions, a computer determines the combination that comes closest to the target weight. The fully automated calibration of the proprietary load cells ensures the highest accuracy and availability by means of calibration weight. As Valdas Keršys, Maintenance Manager explains, “The accuracies are incredible, the investment has paid off in a very short time. The fully-automated calibration was another major advantage in our purchasing decision. “The mean value, the critical value for the calculation of the giveaway, is less than 1% of the target weight. After the actual weighing process, the accurately weighed portions are transferred to the product transfer system designed specifically for this application. A form fill seal machine, tray line and a thermoforming machine are fed without any problem. With target weights of 250g to 5000g, the outputs here are up to 80 weighings per minute for deep-frozen goods and up to 42 weighings per minute for fresh poultry. Since the KG Group requires frequent product changes, up to 38 different products are run on one system this was key to the purchase for Valdas Keršys. Another key criteria to the purchase was the quick and tool-free removal of product contact parts, which effectively reduces the systems’ down time for cleaning and maintenance work to a minimum. Wash racks, which simplify the cleaning process many times over, have been mounted on each platform.

Using the partial portions, a computer determines the combination that comes closest to the target weight. The fully automated calibration of the proprietary load cells ensures the highest accuracy and availability by means of calibration weight. As Valdas Keršys, Maintenance Manager explains, “The accuracies are incredible, the investment has paid off in a very short time. The fully-automated calibration was another major advantage in our purchasing decision. “The mean value, the critical value for the calculation of the giveaway, is less than 1% of the target weight. After the actual weighing process, the accurately weighed portions are transferred to the product transfer system designed specifically for this application. A form fill seal machine, tray line and a thermoforming machine are fed without any problem. With target weights of 250g to 5000g, the outputs here are up to 80 weighings per minute for deep-frozen goods and up to 42 weighings per minute for fresh poultry. Since the KG Group requires frequent product changes, up to 38 different products are run on one system this was key to the purchase for Valdas Keršys. Another key criteria to the purchase was the quick and tool-free removal of product contact parts, which effectively reduces the systems’ down time for cleaning and maintenance work to a minimum. Wash racks, which simplify the cleaning process many times over, have been mounted on each platform.

“MULTIPOND’s features and technology were extremely advantageous for the success of the project i. Drawing on its long-standing experience in weighing the most difficult products, the company was able to offer advice and support. All MULTIPOND systems have run smoothly since installation and are completely reliable” says Keršys.

MULTIPOND has been an owner-managed German company since the very beginning. Drawing on more than 70 years’ experience in industrial weighing technology, we are a pioneer in this sector. Our success is based on the high quality and excellent technical standard of our weighing systems. We consciously commit to a high level of vertical integration, as well as production exclusively in Germany. Customer focus has become our corporate maxim. A team of more than 300 employees commits worldwide to offer our customers from the food and non-food sectors optimized, unique solutions tailored exactly to their requirements at all times. Sales, project planning and service are handled by the headquarters in Germany, by the four subsidiaries in France, the Netherlands, England and the USA, and by a worldwide network of agents.