Sustainable, hygienic, and efficient packaging equipment that helps the bakery industry save operating expenses.

A move toward green/sustainable packaging solutions has become a priority as many bakeries are beginning to look at all aspects of the line and how they can improve efficiency and use less energy with each piece of equipment. Looking at challenges with labour and material costs, as well as achieving sustainability goals require the equipment to have improvements, not only for efficiency in energy but in set up and maintenance processes as well.

Repeatability with set up and changeovers has been a great improvement to equipment efficiency. Making the process simple for the operator will save time on labour and materials. It used to be that operators would waste large amounts of material and product setting up the machine, whereas now, the process has improved so that the equipment has simple, repeatable steps, and after a few minor adjustments, it is “start and go”. This saves labour, material, and product.

Formost Fuji flow wrappers are designed to increase efficiency and help bakeries reach their goals for a sustainable packaging solution. Features such as a shorter film route that reduces material or an obstruction detection sensor that prevents material waste are just a few of many features that positively impact a bakeries carbon footprint. Formost Fuji’s induction heat technology for the fin sealers reduces energy usage which is a big part of meeting sustainable goals. The Alpha 8 flow wrapper series is highly effective at creating a tightly wrapped package, and when a bakery is running thousands of packages a day, the material savings really add up. With adjustable forming boxes and guides, set up on a Formost Fuji flow wrapper takes less time, saving labour, materials, and product. Training becomes easier and faster as well.

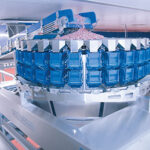

Formost Fuji bagging machines are the most dependable baggers on the market. Built strong and simple to operate with quick and easy changeovers, the baggers integrate smoothly with automated systems such as the inline bun system, bagel system, or English muffin system. These systems offer a more efficient bagging line for increased productivity and reduction in labour costs.